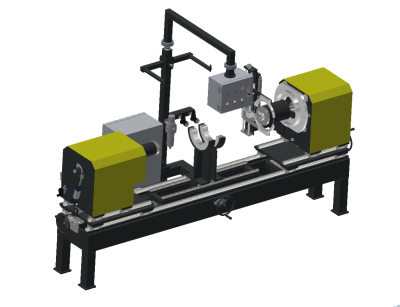

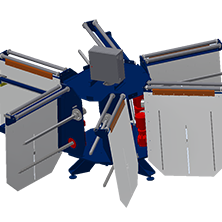

AIRSPRING VULCANIZER

Sleeve type airspring vulcanizer is used to vulcanize sleeve type airspring bellows. It equipped with 4 vulcanizing stations, and is suitable of diameter between 65mm to 95mm, and the length is 1050mm.

AIRSPRING BELLOWS BUILDING SYSTEM

This machine is manully feeding building machine, It is suitable for diaphragm type bellows diameter between 120mm to 300mm, and the length between 300mm to 900mm.

AUTOMATIC AIRSPRING BUILDING MACHINE

Automatic airspring building machine is used to make diaphragm airspring bellows. It is suitable for diameter between 120mm to 300mm, and length between 300mm to 900mm bellows.

2 HEATING 1 FORMING THERMOFORMING MACHINE

2 heating 1 forming thermoforming machine,also known as double thick sheet thermoforming machine, is mainly used for making plastic products with double layer structure, such as logistics pallets, shelf pallets and logistics turnover boxes which need to bear load, and containers which need heat preservation and heat insulation. It is suitable for most thermoplastics.

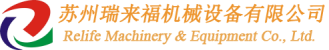

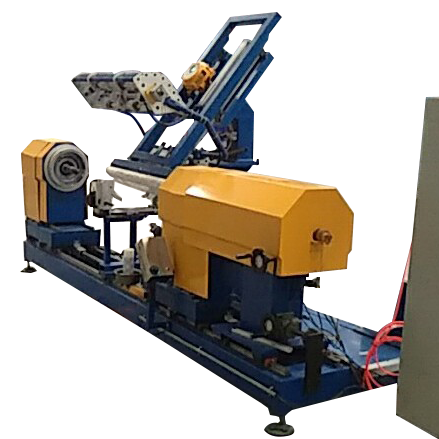

SLEEVE BUILDING LINE

Sleeve building line is used to produce sleeved type air spring bellows with diameter below 80mm. The building line includes three in one feeding rack, conveyor belt type building machine and four station vulcanizing machine. 1 meter long sleeve bellow can be made at one time with high production efficiency.

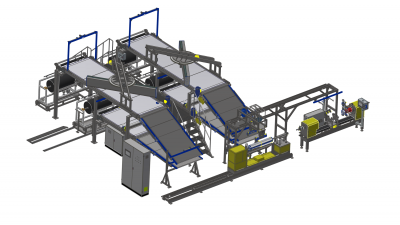

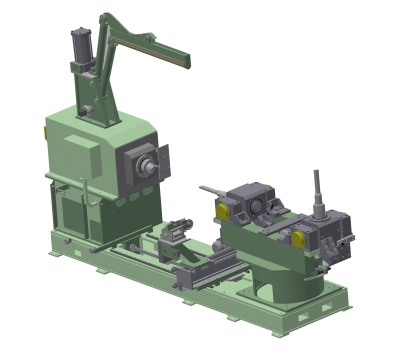

CORELESS ROLLING-UP MACHINE

Coreless rolling-up machine or air spring beading machine, used for air spring bellow, is to wrap the steel rings into rubber sheet at the two ends of the bellow after bellow forming. After rolling up process, the bellow can then be holed and vulcanized. Rolling-up is an important process in the production of air spring.

AUTOMATIC PUNCH MACHINE

Punching machine, also known as bellow punching machine, is an auxiliary equipment in the production of air spring. It is used to punch the bellow at the joint of the ring and the rubber before vulcanization. These punched holes are opened to the air to ensure the precision fitting of the ring and the rubber when the air spring is vulcanized. This can ensure the quality of the air spring.

SEMI AUTO THICK SHEET THERMOFORMING MACHINE

SH series semi-auto thick plate thermoforming machine is used for forming plastic which thickness is below 12mm. Including heating station, forming station, the machine needs to be equipped with additional trimming station, vacuum system and hydraulic system. The machine is used for making large plastic products such as traveling case, bathtubs, pit tubs, refrigerator inner and so on.

IN-MOLD CUTTING SERVO THERMOFORMING MACHINE

In-mold cutting servo thermoforming machine integrates punching station into forming position, which greatly improves the precision of products and simplifies the structure of the machine. It usually includes heating station, forming punching station and stacking station. Used to produce plastic products with thickness below 1.5mm, such as fast food box, fruit box and so on.

SMALL SEMI-AUTO BLISTER MACHINE

Small semi-auto thermoforming machine, namely sampling thermoforming machine is designed for small batch or samples products. It takes the principle of thermoplastics vacuum thermoforming. The machine has light weight, small size and easy operation. The heating station and forming station work at the same time, with high production efficiency.

SERVO TURNOVER CUP THERMOFORMING MACHINE

The is the most advanced cup making machine in China, which adopts positive and negative pressure forming and in-mold punching structure, and has the characteristics of high speed, high efficiency and convenient packaging.Suitable for plastic cups with material thickness of less than 2.5mm and forming height of less than 200mm.

FULLY AUTOMATIC PRESSURE & VACUUM THERMOFORMING MACHINE

3-station automatic positive and vacuum plastic thermoforming machine, used for thermoforming of thermoplastic plastic with thickness of 0.2-1.5mm or less, widely used, such as food box, fruit box, egg tray, electronic tray, etc.

PVC WALL PANEL THERNOFORMING MACHINE

The equipment is used for making PVC plastic wall panels, decorative interior wall panels and other materials of plastic wall panels. As long as the replacement mold, it can be used to make large thin sheet plastic parts.

1 HEATING 2 FORMING THERMOFORMING MACHINE

1 heating 2 forming thermoforming machine is used for the production of PE, PP, PVC, PS, ABS, PMMA and other conventional engineering plastic products, such as electronic pallet, vehicle interior decoration board, decorative wall panel and other large area products.

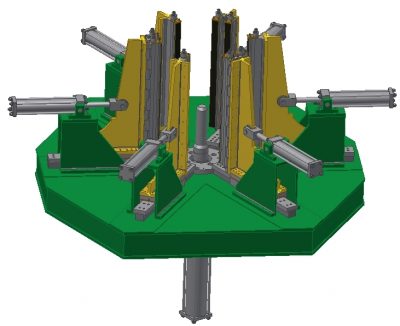

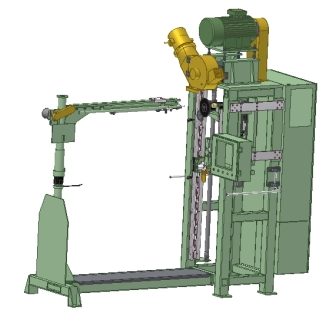

BELLOWS BUILDER

Bellows builder is used to make rubber bellows for airspring. The inner layer, the cord fabrics and the outer layer rubber sheets are rolled into the bellows through the building drum.

Then turn up by the flip over device, the steel rings are wrapped into the bellows.

AIRSPRING BUILDER RACK

The rack is the supporting equipment of the bellows building machine, which is used for the fixed-length cutting of sealing sheet, endurance cord fabrics and oil-resistant outside rubber sheet. The rack has various forms. Our company’s six station vertical rack can be used for fixed length cutting of up to six kinds of materials.

AIRSPRING LIFETIME TEST MACHINE

Airspring lifetime test machine is designed referring to the national stand, GT/T 13061-2017.It is used to test bellows type and combined type airspring.

SLEEVED TYPE AIRSPRING TEST MACHINE

Sleeved type airspring, also called sleeve type airspring. This machine is designed according to national standard GB/T 13061-2017, and used for testing the longevity of diaphragm airspring.

SPLIT TYPE HYDRAULIC THERMOFORMING MACHINE

Split type hydraulic thermoforming machine is used for the production of plastic products with thickness of 1-2.5mm coil material, high speed and high efficiency. Such as electronic tray thermoforming, vehicle interior panel thermoforming, decorative wall panel thermoforming, tub thermoforming, refrigerator liner thermoforming and other larger area products thermoforming.

SLAB BUILDER

rubber belt building machine is used for the forming work of rubber slab before vulcanization in belt production line, including three parts, AB-head building machine, tension automatic control pay off machine and six or eight stations rack.

THERMOTRNSFER PRINTER

Thermal transfer printer uses the principle of melting instant ink at high temperature, from one medium to another medium transfer process.

PITCH GRINDER

The pitch grinder,commonly known as small grinder,is used for grinding the shape and teeth of the belt. After the slab is cut into a single belt, a pitch grinder is used to grind the desired teeth shape.