SMALL SEMI-AUTO BLISTER MACHINE

-

Overview

SP series manual thermoforming machines are designed for small batch or samples products. It takes the principle of thermoplastics vacuum thermoforming. The machine has light weight, small size and easy operation. The heating station and forming station work at the same time, with high production efficiency.

-

Machine Structure

The feeding is driven by stepping motor, low cost, high precision, the maximum diameter of the material roll can reach 450mm, the width of the material coil 610mm (fixed value).

Heating design has upper and lower electric furnaces, according to the actual need to enable the lower electric furnaces, heating tile using standard heating tile, easy to purchase accessories in the future. Temperature control module, PLC and touch screen linkage control, high degree of automation, fast response, high accuracy, temperature setting and current temperature display, are realized in the touch screen.

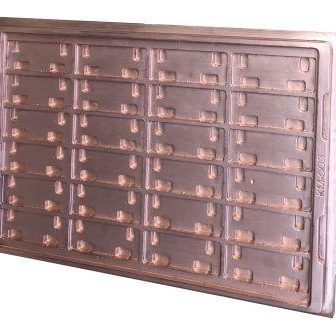

Forming station, the cylinder drives the upper and lower die for product forming, the forming die is installed in the lower die table, can be vacuum pumping and cooling water cooling, the upper die table can be free to add auxiliary molding tooling according to the shape of the product.

The layout is driven by rodless cylinder, and the height is adjustable, which can flexibly adapt to different product needs.

This machine is not equipped with cutting station, the customer needs to buy the cutting station, the cutting area is not less than 700×800, the cutting force is not less than 35 tons.

-

Machine Parameter

| 1 | Overall Power | 30KW(excluding cooling machine) |

| 2 | Max Forming Size | 560x610mm |

| 3 | Max Forming Height | 120mm |

| 4 | Max thickness | 2mm |

| 5 | Machine Dimensions | 2000*1900*1230mm |

| 6 | Weight | 800Kg |

| 7 | Power | AC380V,50Hz |

| 8 | Air | 0.7MPa |

| 9 | Customer Supplied | Air compressor、Tank(no less than 100L)、

Cooling Machine(If need) |

-

Configurations

| 1 | PLC、HMI | Simens |

| 2 | Pneumatic | Airtak |

| 3 | Vacuum Pump | Domestic Famous |

| 4 | Step Motor | Domestic Famous |