2 HEATING 1 FORMING THERMOFORMING MACHINE

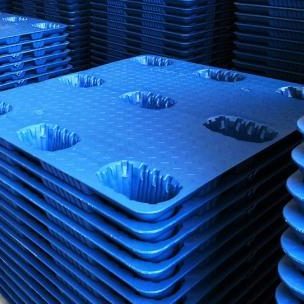

2 heating 1 forming thermoforming machine,also known as double thick sheet thermoforming machine, is mainly used for making plastic products with double layer structure, such as logistics pallets, shelf pallets and logistics turnover boxes which need to bear load, and containers which need heat preservation and heat insulation. It is suitable for most thermoplastics.

2 heating 1 forming thermoforming machine can also be used for making plastic products with long heating time and short forming time. Heating on two side stations, sharing a forming station, stagger the forming time, give full play to the machine’s performance. It is suitable for making large plastic products such as machine parts pallet.

The machine adopts left and right structure, sharing the middle forming station, both sides are equipped with loading station, unloading station. Through mode switch, it can produce double plastic products, can also produce single plastic products.

The forming station is driven by hydraulic cylinders to ensure that there is enough clamping force to ensure the forming quality.

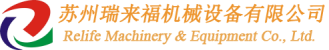

Because the finished product is relatively thick, after the blank is made, it needs to be placed for a period of time. After it is completely cooled and no longer shrinks and deforms, it can be trimmed. Trimming machine is usually used for trimming, after trimming is the finished product.

Trimming can be equipped with our three – axis or five – axis engraving machine. Our engraving machine adopts the optimal cost control, cost-effective.

The machine adopts PLC and touch screen control to automatically control of feeding, heating, forming and unloading . Centralized temperature control mode is adopted to ensure the molding quality of products.

AH21 series double thick sheet thermoforming machine produced by our company, the maximum forming size 1800×2000, the maximum forming depth 400.