SLAB BUILDER

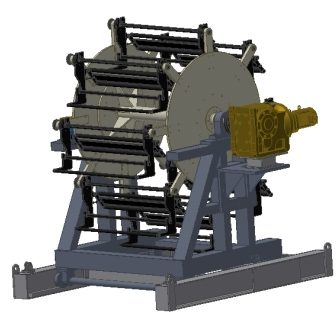

Rubber slab builder is used for the forming of rubber slab before vulcanization in the belt production line, including three machine, AB-head building machine, tension automatic control pay off machine and six or eight stations rack. The number of rack stations depends on the production process.

The main machine is used for winding cords and wrapping rubber sheet, with the following functions: wrapping rubber sheet, winding cords, making slab, etc. Including the headframe, lining device, AB head conversion table, press-roll device, hydraulic system and other parts, this machine is suitable for mold diameter of 160-850mm, mold length of 1000mm.

Tension automatic control pay off machine is used for paying off cords according to the set tension requirements, paying off system can accurately control the tension of the cords. Each set of tension automatic controls two wires at the same time. Ensure uniform lining density, stable cord tension, tension adjustment range: 10-160N.

The material rack is used for rubber rolls storage add unwinding, with a total of six or eight stations. It can electrically rewind the padding. The diameter of the material roll is about 90-420mm, and the diameter of the padding cloth roll is 90-250mm.

Design capacity, according to the skilled operators, the cutting belt is formed on the 1000mm girth V10 belt mold for evaluation, which is 50-60 rubber sets /8 hours.

HMI is used to control the whole system operation, the operator enters the production number ID through the HMI or by the barcode gun, the touch screen displays the ID number, the mold circumference, the mold number, SPI, the cord tension and the cord number and other information.