SLEEVE BUILDING LINE

Sleeve building line is used to produce sleeved type air spring bellows with diameter below 80mm. The building line includes three in one feeding rack, conveyor belt type building machine and four station vulcanizing machine. 1 meter long sleeve bellow can be made at one time with high production efficiency.

Sleeved type air spring is widely used in all kinds of machine tools, cars, motorcycles, trains, ships, aircraft and tanks and other equipment.

In the automotive application, sleeved type air spring is applied to the cab seat, cab suspension, light commercial vehicle chassis suspension. The driver’s seat in commercial vehicles is often fitted with a sleeved type air spring, which is compact and easily integrated into the seat bracket, transforming the driver’s seat into an ergonomically comfortable workspace, reducing the driver’s fatigue and reducing health risks.

The air spring suspension in cab suspension system adopts the four-point suspension form between the cab and the frame to improve the comfort of the vehicle.

Because of relatively low cost, relatively simple production process, Sleeved type air spring is popular, huge market demand.

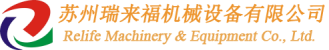

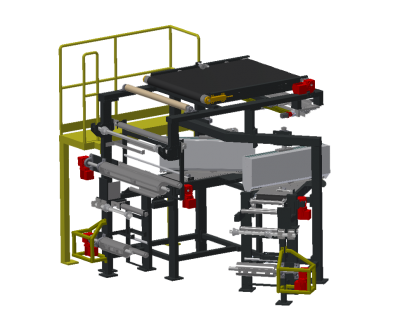

The three-in-one material rack is with two rubber sheet s, one cord fabrics position. According to the set program,the rack supplies rubber sheet and cord fabrics in turn. Cord fabrics cutting adopts automatic cutting, without manual tearing, that improves the work efficiency, and reduce the working intensity.

Conveyor belt structure is used for the building machine. With the projector positioning assistance, the rubber sheet and cord fabrics can be accurately spread on the conveyor belt, and then roll the material into a bellow through the roller.

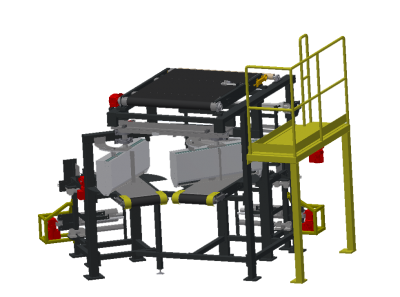

The vulcanizing machine is vertical and has four stations, vulcanizing four 1 meter long bellows at a time, with high efficiency. Using double high pressure steam for vulcanization, the bellow quality is good.

Welcome new and old customers to custom large size sleeve building line.