BELLOWS BUILDER

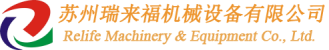

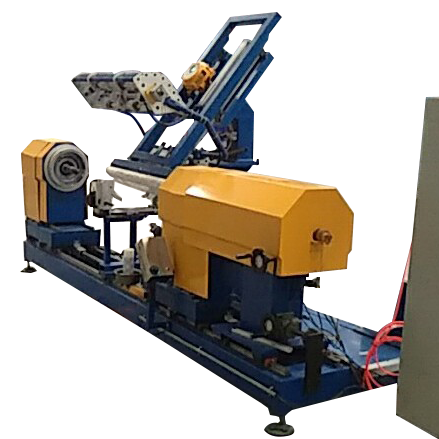

Bellows builder is used to make rubber bellows for airspring. The inner layer, the cord fabrics and the outer layer rubber sheets are rolled into the bellows through the building drum. Then turn up by the flip over device, the steel rings are wrapped into the bellows.

The speed of the building machine determines the production line capacity, the traditional forming machine, can only be used for the shaping of bellows, and has no flip over function. Our building machine can flip over the two ends at the same time, the efficiency is quite higher than the traditional way.

The machine can easily switch the production of different products, high efficiency, especially suitable for small batch production. It is really one machine in hand, everything is free. The bellows parameters are set by the touch screen. After setting the formula, it is convenient to switch between different products.

Spindle motor, pressure wheel motor, steel ring positioning and film width are controlled by servo motor, and the movement of the flip over devices is also controlled by servo motor, so as to ensure accurate positioning of the length of the product.

This equipment is used to make bellows 124-230mm in diameter and 300-700mm in length.

The builder needs to be used together with supporting material rack.

Equipment parameters:

Capacity: 6 minutes/drum;

Installed power: 4-6KW;

Equipment weight: 1950Kg;

Dimensions: 4100x1560x2460 (height)

Equipment configuration:

- PLC, HMI: Siemens;

- Servo motor: Mitsubishi;

- Reducer: SEW;

- Linear guide rail and ball screw: Taiwan HIWIN;

- Bearings: NSK, SKF;

- Pneumatic components: SMC, FESTO, CKD