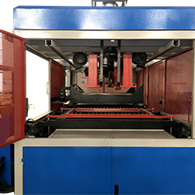

SEMI AUTO THICK SHEET THERMOFORMING MACHINE

SH series semi-auto thick sheet thermoforming machine is a classic thermoforming machine, which is used for the thermoforming of plastic thick plate with thickness below 12mm. The machine uses plate as raw material for discontinuous forming process. It can be used to make large area and large depth of products. The machine adopts negative pressure forming double mold structure, the lower mold forming, the upper mold according to the requirements of the product and shape to determine the structure, to aid product forming. It uses manually feeding and taking out, and its’ heating method is according to the material and thickness of the material, which can choose ceramic infrared heating or halogen short-wave quartz tube heating. Machine structure is simple, equipment investment is small, quick effect.

The machine is equipped with advanced automatic control system, temperature control system, human interface (HMI) input system. Through HMI and PLC to the whole process of automatic control, high degree of automation, it is easy to operate.

Production process: manual feeding – press frame going down to hold material – upper and lower electric furnace automatically moving out to heat – heating completion – upper and lower heating furnace automatic retracted – blowing bubble (optional) – the mold rise —– vacuum forming – delay cooling – air blowing to strip – the mold retracted – press frame rise – manual take out the product.

The machine includes the following stations: heating station, forming station, the machine needs to be equipped with additional trimming station, vacuum system and hydraulic system.

The heating station adopts far infrared ceramic heating tile or halogen short-wave heating tube, with thermocouple multi-point temperature control, it has uniform temperature field. The temperature of each point can be set freely and independently on the HMI screen, effectively ensuring the quality of the subsequent finished products.

The forming station adopts a plurality of hydraulic cylinders synchronous drive, to ensure that the levelness of the forming table. The forming station is equipped with a clamping material press frame, to ensure the stability of the material in the forming process.

As to trimming station, according to the different shapes of the products, different designs are adopted to meet the requirements of various products.