PLASTIC THERMOFORMING MACHINE

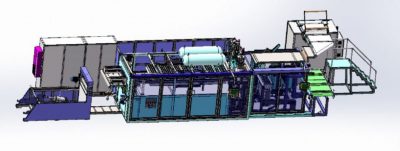

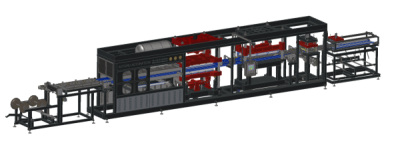

Plastic thermoforming machine, also known as blister machine, taking the use of thermoplastic physical properties, for the production of thermoplastic products. Usually there are heating station, forming station, cutting station and stacking station composition. under the control of PLC, so that all stations work together to produce high quality plastic products.

Plastic thermoforming (blister) technology, is the process of thermoplastic sheet (plate) material into various products of plastic processing technology. First, the plastic sheet (plate) material is heated in the heating furnace to the soft status, and then placed in the forming mold, under the external forces (vacuum, positive pressure or machinical force), so that it closely adhere to the surface of the mold, forming and bonding surface detailed shape.After cooling shaping, trimming and other processes, get the desired products.

Plastic thermoforming (blister), usually used in the manufacture of thermoplastic products.Products with large forming surface and uniform thickness can be produced by this method.Compared with injection molding, it has the advantages of high production efficiency, low equipment investment and low mold cost.Suitable engineering plastics including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), acrylonitrile – butadiene – styrene (ABS), polymethyl methacrylate (PMMA) and polyethylene terephthalate (PET), etc., material thickness less than 1.5 mm is often called chips, above is called the thick sheets.

Thermal forming process consists of vacuum forming method, pneumatic forming method, die forming method, plunger – assisted pressure forming method, solid – phase forming method and double – sheet thermal forming method.According to different products, different materials and different thickness, choose the appropriate forming process.

Products that can be made, such as beverage cup, fruit boxes, fast food box, egg holder, electronic tray, car interior, agricultural car roof, refrigerator liner, logistics transport pallets and so on, thermoforming is widely used.

With the continuous improvement of the automation technology, a variety of automatic blister machines boom.

we make 2 station fully automatic pressure vacuum thermoforming-machine, 3 station fully automatic pressure vacuum thermoforming-machine, servo turnover cup make machine,

PVC Wall Panel Thermoforming Machine, Small semi-auto thermoforming machine, Split type hydraulic thermoforming machine, 1 heating 2 forming thermoforming machine ,

2 heating 1 forming thermoforming machine and custom any special machine