STRIPPER

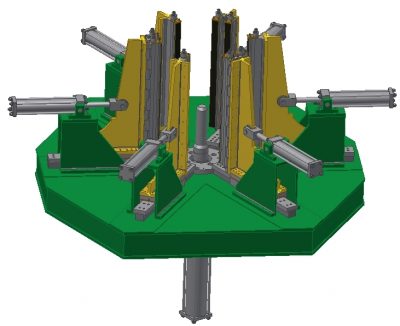

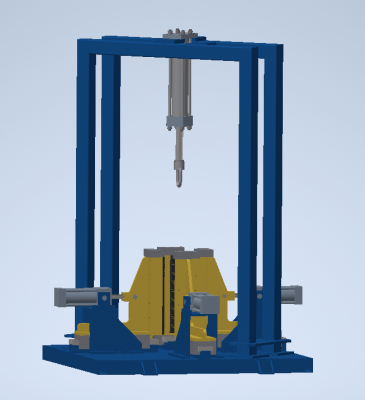

Stripper is used for separation of vulcanized timing belt slab, mini-pitch belt slab, V belt slab, etc. from the mold.

Equipment includes main platform, guide rail, the clamping cylinder, clamping cylinder seats, demolding cylinder, stripping head, demolding claw, hydraulic station, hydraulic system, hydraulic hose, hydraulic pipe, and the main electrical box. Site-equipped operating electrical box is used to control the clamping cylinder forward, backward, stripping the rise and fall of the oil cylinder.

Stripper meets mold diameter 160mm – 850mm, height 1000mm.

The stripper jaw is divided into two groups, each group has three oil cylinders, one group need to be synchronized, using synchronous balance valve to control. The hydraulic system is divided into three ways to control the rise and fall of the main cylinder, and two ways to clamp (three claws in each way). Each way can adjust the oil pressure and flow.

Because the mold structure of each manufacturer is different, the stripper shaft needs to be customized according to the mold drawing of the customer.