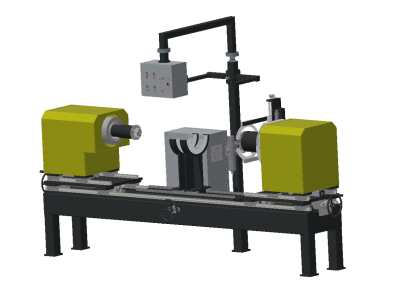

CORELESS ROLLING-UP MACHINE

Coreless rolling-up machine or air spring beading machine, used for air spring bellow, is to wrap the steel rings into rubber sheet at the two ends of the bellow after bellow forming. After rolling up process, the bellow can then be holed and vulcanized. Rolling-up is an important process in the production of air spring.

The steel ring in the air spring plays a limiting and strengthening role, with the steel ring, the cover plate and piston of the air spring can be installed, then the air spring can become a closed container, and the air spring can play its excellent shock absorption performance.

At present, most domestic manufacturers use manual rolling-up, the mechanization degree, rolling-up speed, production efficiency is very low, the work intensity is quite large.

Our company developed the coreless rolling-up machine, using the airbag structure, without the mandrill, automatic rolling-up. This machine is suitable for the diameter range of 120-300mm, length range of 280-700mm straight bellows and cone bellows. It works automatically, without manual intervention, fast speed. As a result of the use of airbag, the bonding surface uniform, bright appearance, less air in the joints etc.. working with our punch machine, it can produce all kinds of perfect bellows.

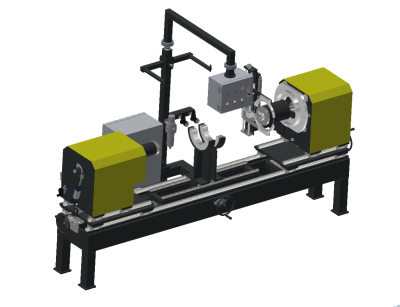

Our company building machine has been equipped with the rolling-up mechanism at both ends. The machine can build and roll up the bellow at one time. For new projects, we suggest using this machine.