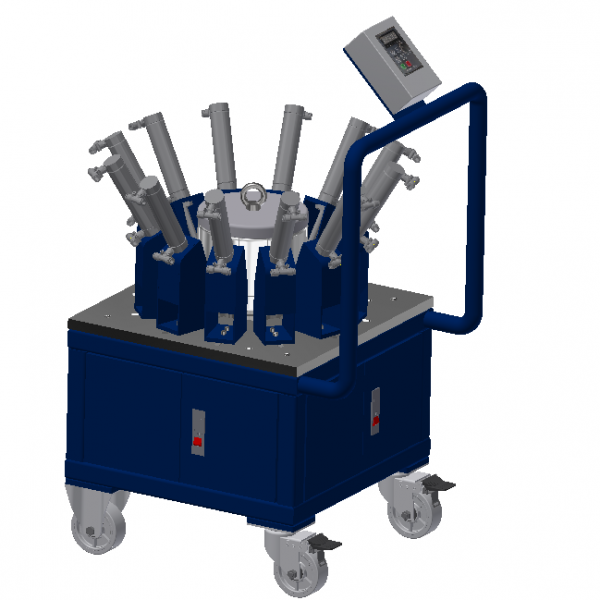

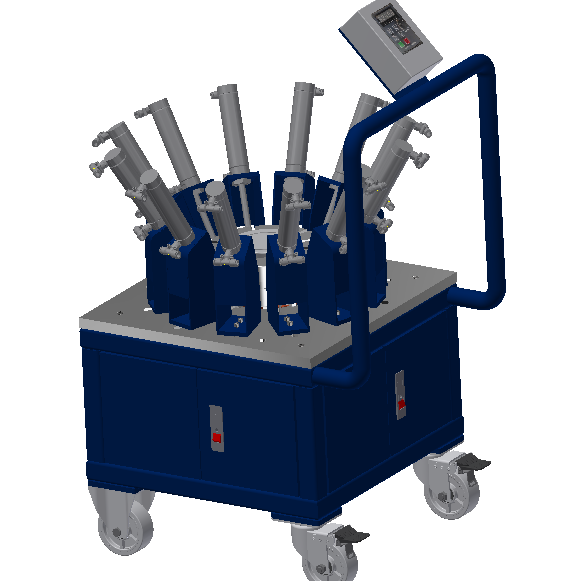

AUTOMATIC PUNCH MACHINE

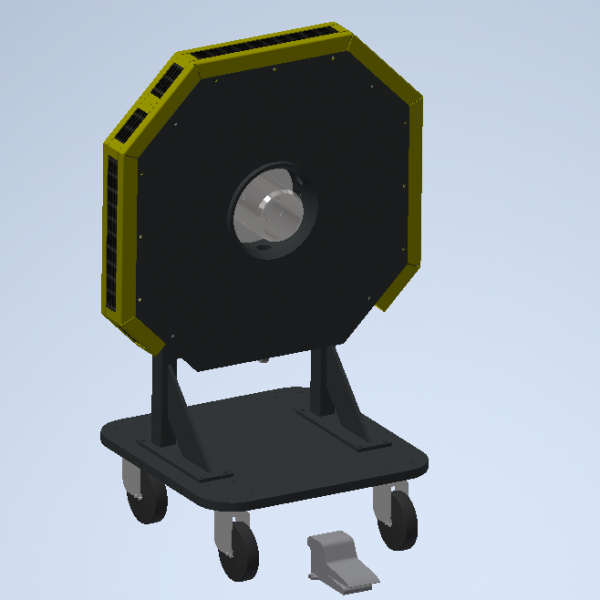

Punch machine, also known as bellow punch machine, is an auxiliary equipment in the production of air spring. It is used to punch the bellow at the joint of the ring and the rubber before vulcanization. These punched holes are opened to the air to ensure the precision fitting of the ring and the rubber when the air spring is vulcanized. This can ensure the quality of the air spring.

In the process of rolling up, air is trapped between the steel ring and the rubber sheets. This air will expand and bubble when the bellow is exposed to the high temperatures of vulcanization. In case the air is not deflated, it will lead to the steel ring peel off the rubber. In the future use, it will result in the air spring burst, not only reduce the service life of the air spring, but also cause safety accidents.

Use this machine to punch at the joint of steel ring and rubber sheet. In the next vulcanization process, under the vulcanization pressure, the trapped air will be deflated, so that the rubber closely fit with the ring, and the rubber sheet inside and outside the ring will be melt gatherer.

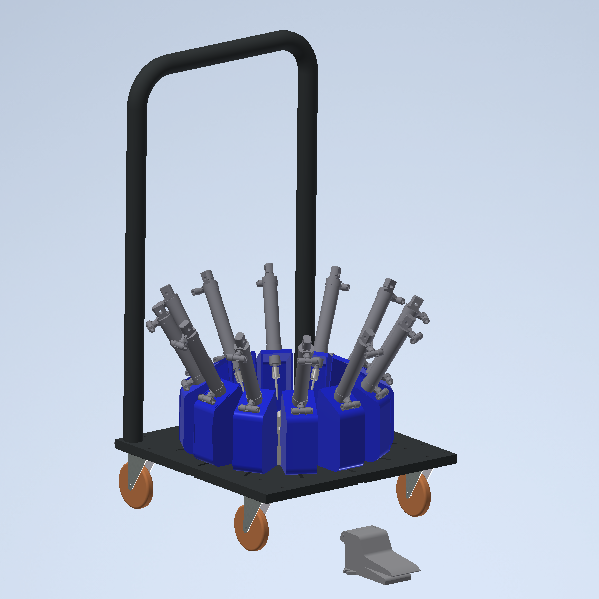

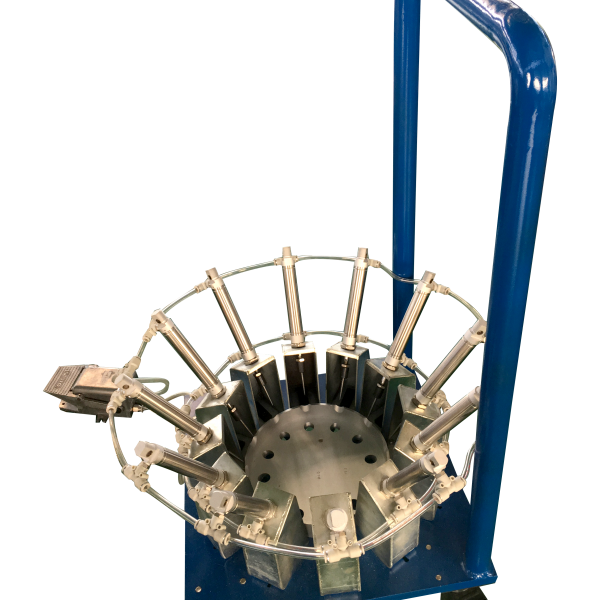

Normally, there are two kinds of the punching machine, vertical punching machine and horizontal punching machine. Horizontal punch machine are used for small diameter air spring, and vertical punch for large diameter air spring. These punches are usually semi-automatic and require manual rotation of the bellow to punch holes in different positions.

Our newly developed fully automatic punching machine is no need manual intervention, the operator can set the number of punching according to the need, the machine will aromatically punch according to the set program, punching evenly. The punching effect is quite good. The machine is suitable for all sizes of the bellow. The efficiency is 10 times more than the traditional punching machine.